Originally built by Roadster Shop, this is a super cool truck that needed a little love!

Rear suspension jacking forces are something that’s really overlooked. This truck had a Roadster Shop chassis installed, but unfortunately the rear geometry wasn’t correct for the ride height of the truck.

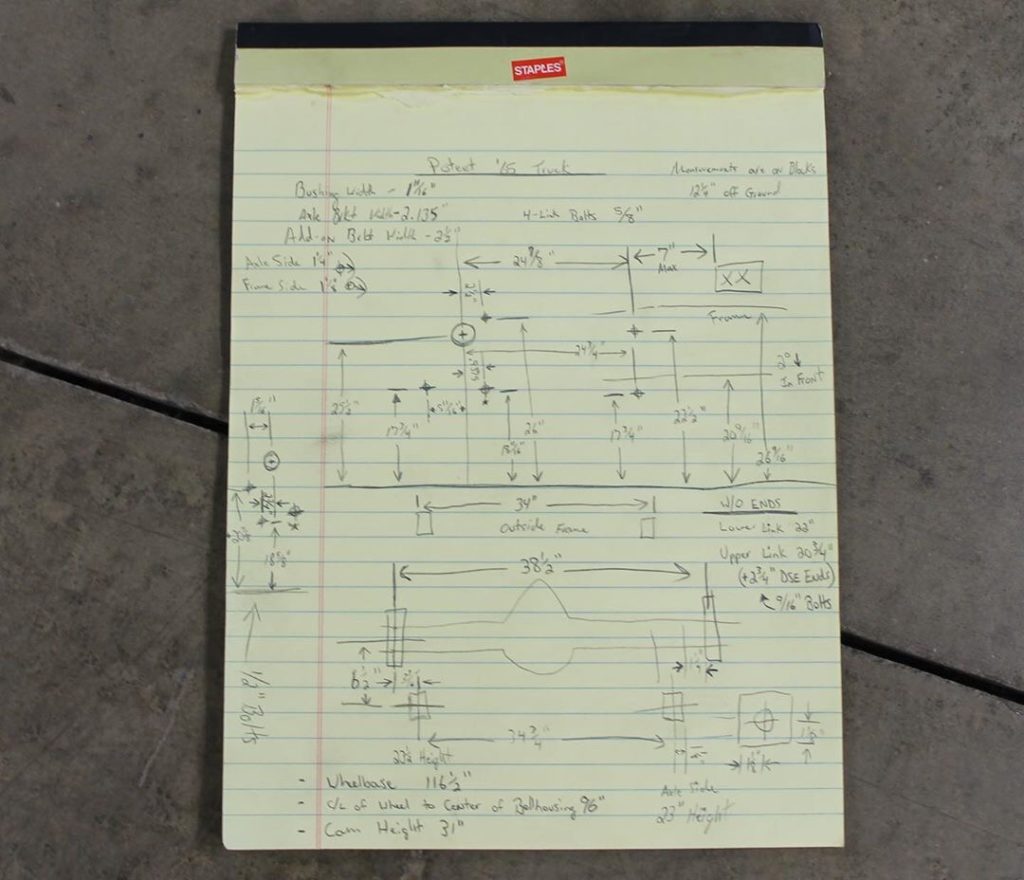

Under braking, the rear of the truck would raise dramatically. Under acceleration, the truck would get little traction out of the hole, and would squat (not from weight transfer, but jacking forces sucking the rear end up into the body). We scaled the vehicle, and determined the center of gravity. We measured all points in space, and determined where to aim the instant center based off weight bias, tire size, power output (to name a few). “Instant center” is where the imaginary lines of the trailing arms intersect in space. This point is instrumental in tuning the rotational forces applied to the frame, through the ring and pinion of a 4-link rear end. Tuned incorrectly, the vehicle will have no performance and can actually be dangerous to drive.

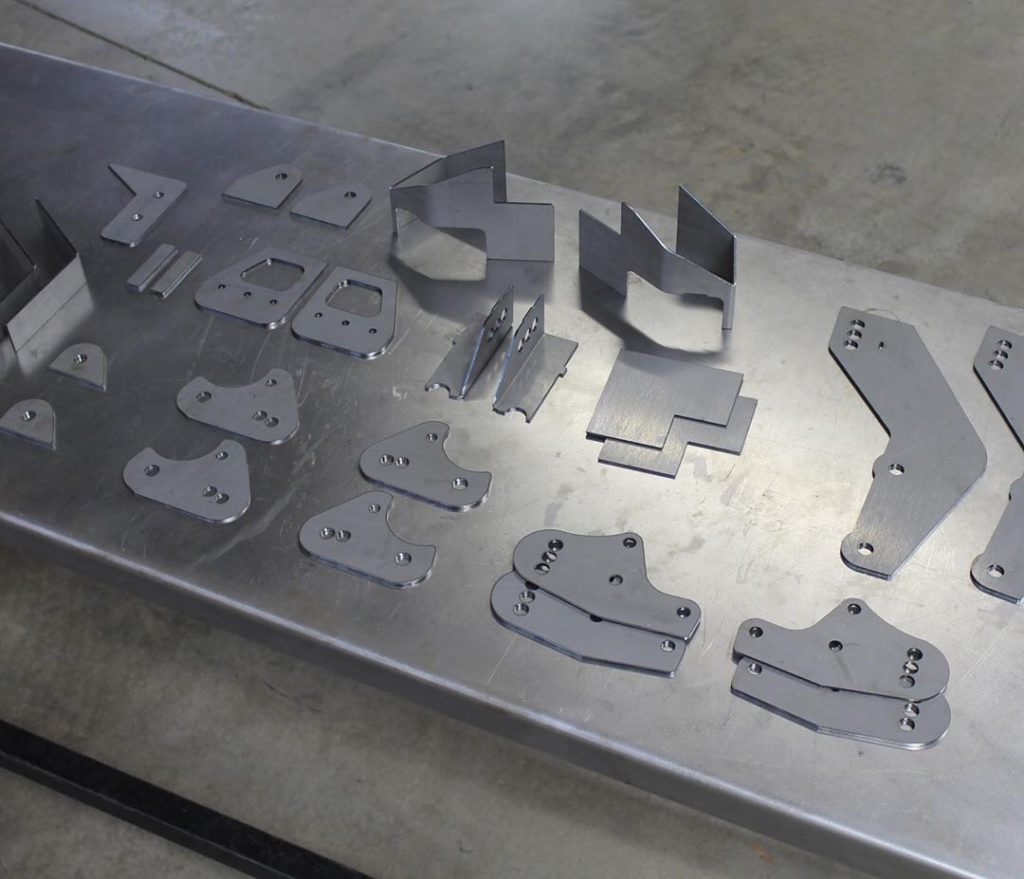

This was an easy way to correct all issues, as we got lucky and could add the appropriate brackets without reinventing the wheel. BEHOLD; a rear suspension that works. The truck now raises .125-.250” in the rear under acceleration (a little over 100% anti-squat), gets total traction under acceleration from 1st gear, and stays flat under braking, dramatically reducing braking distances.

If you look at the picture of the frame bracket, we located off the original points before removing the bracket hanging under the frame. The geometry was off so far, we actually used the old upper trailing arm hole as the new lower trailing arm mount.

All this resulted in a happy customer with quick turnaround!