WHAT WE DO

“Design, engineer & create vehicles and components.”

What exactly do we do?

DESIGN. ENGINEER. CREATE.

“We specialize in high-end metal fabrication and Bespoke vehicle builds. “

The Complete Package

MANUFACTURING & PROTOTYPING

“Small Batch Builds or Runs into the Thousands”

Versatile Manufacturing & Production

VALIDATION & TESTING

“We’re able to achieve Accuracy & Reliability that’s second to none.”

We Know Testing

BUILDING LONG-LASTING RELATIONSHIPS

“We understand how to leverage the right connections.”

An Equally Strong Set of Resources

LATEST NEWS

“Keep up to date with the ACME blog!”

On time and on track!

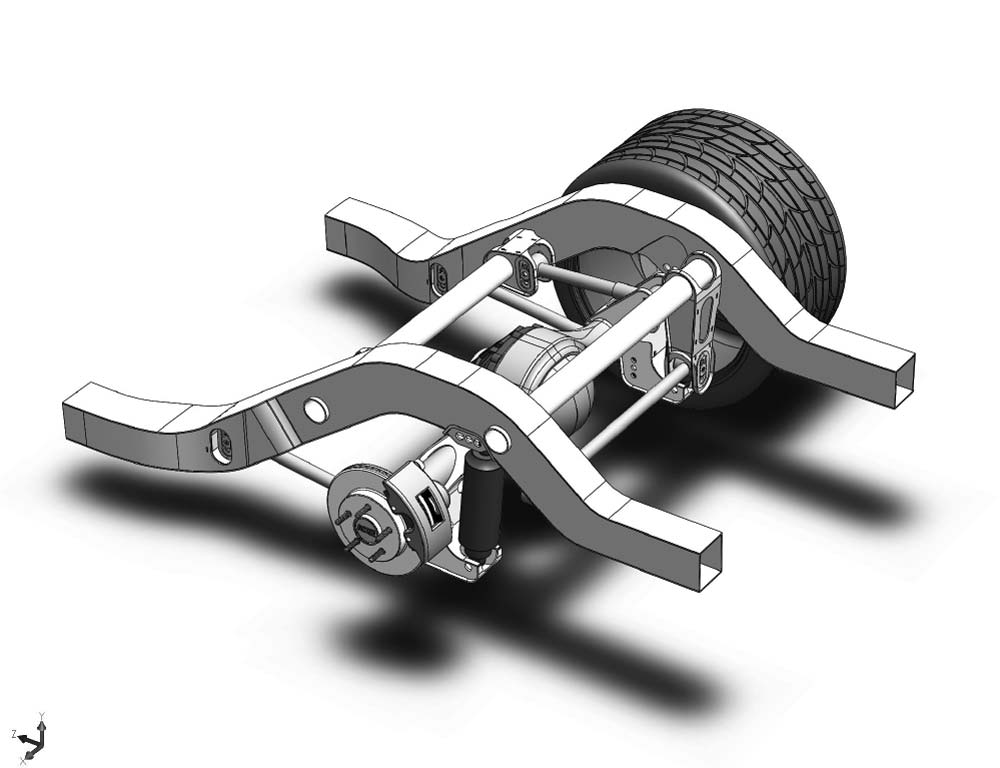

We’re on time and on track to start delivering “Big Stick” Traction Enhancement Modules for 2005-2020 LX platforms in August! Seen here is the first of many shipments of tube laser parts, handily taken care of by our friends at Alabama Laser! Get 100% bolt-in...

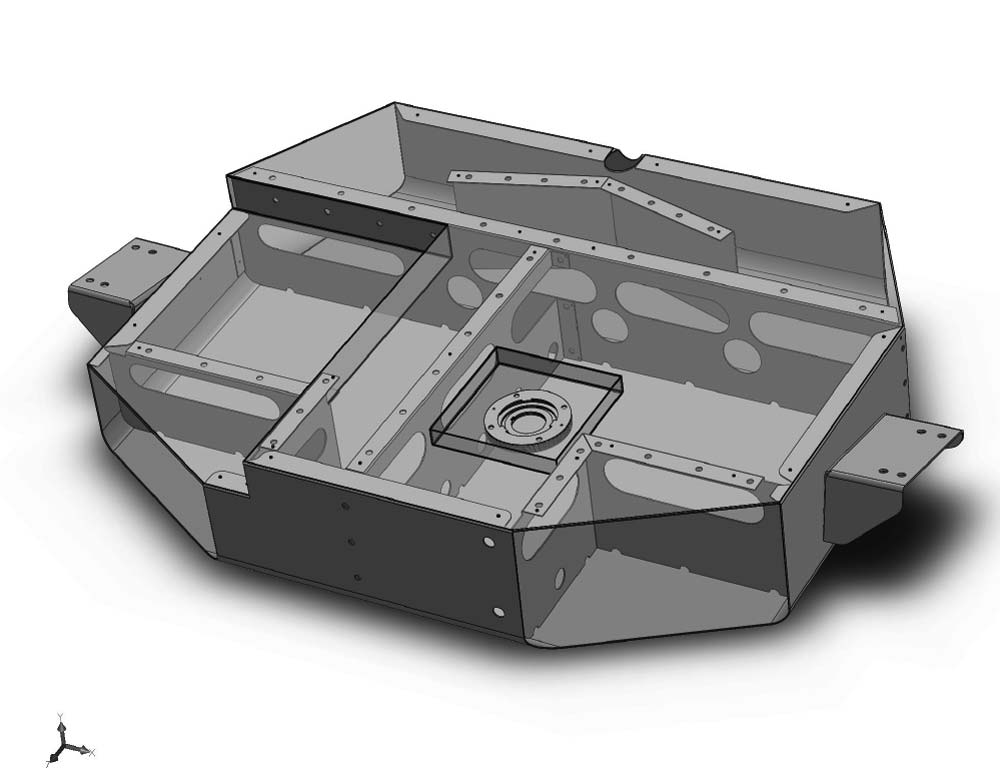

More on the ACME “Big Stick”

Wesley Motorsports has some of the coolest looking cars on the track (and street). This particular blue behemoth sports 355mm tires on all four corners, and like the majority of the Wesley fleet it will also sport the ACME “Big Stick” Traction Enhancement Module....

Package Trays/Speaker Pods available!

Package tray greatness for first and second gen Camaros, with other makes and models available as well! Run 6x9 speakers underneath factory flat shelves, no speakers exposed and no buzzing. Made out of 16 gauge stamped steel. Builder level parts. Email us at...

ACME “Big Stick” with Driveshaft Shop kit

Frank from Driveshaft Shop swung by yesterday with some mockup parts for us! ACME “Big Stick” Traction Enhancement Modules will soon be able to be purchased with a Live Axle Carrier that can be used with the DSS kit! Pre-orders are going fast, get your name in...

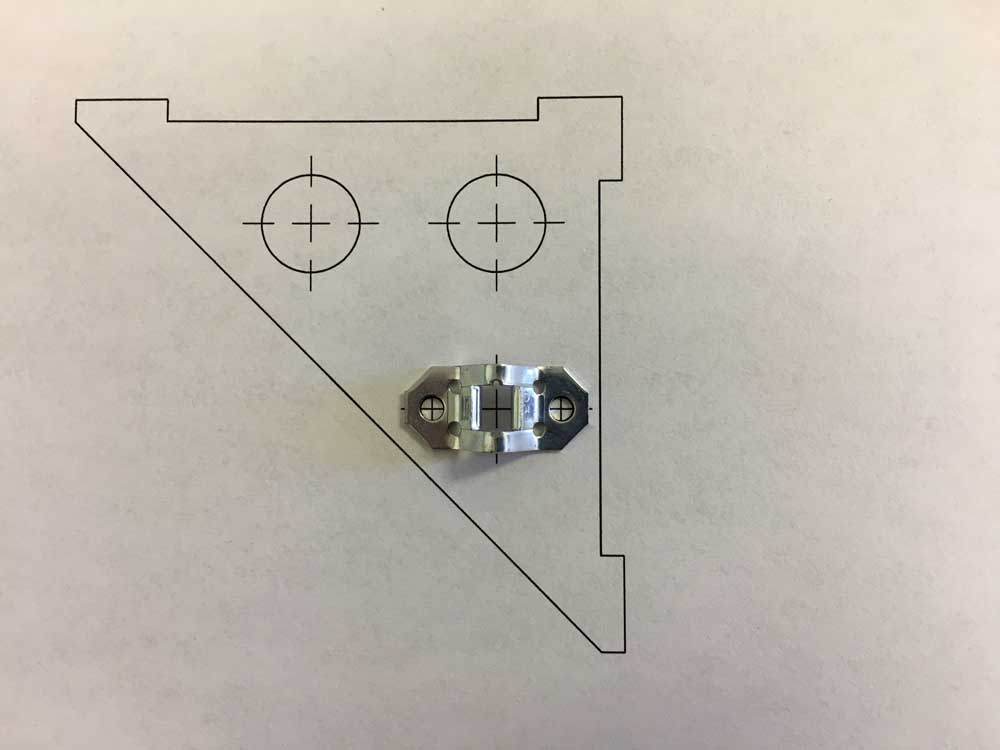

Early Bronco Firewall & Engine Compartment Kit

Introducing another NEW product from your friends at ACME Hi-Performance Laboratories! '66-'77 Early Ford Bronco Firewall & Engine Compartment Kit Constructed of .090” steel, complete with Cleco & spot weld holes for easy alignment and...

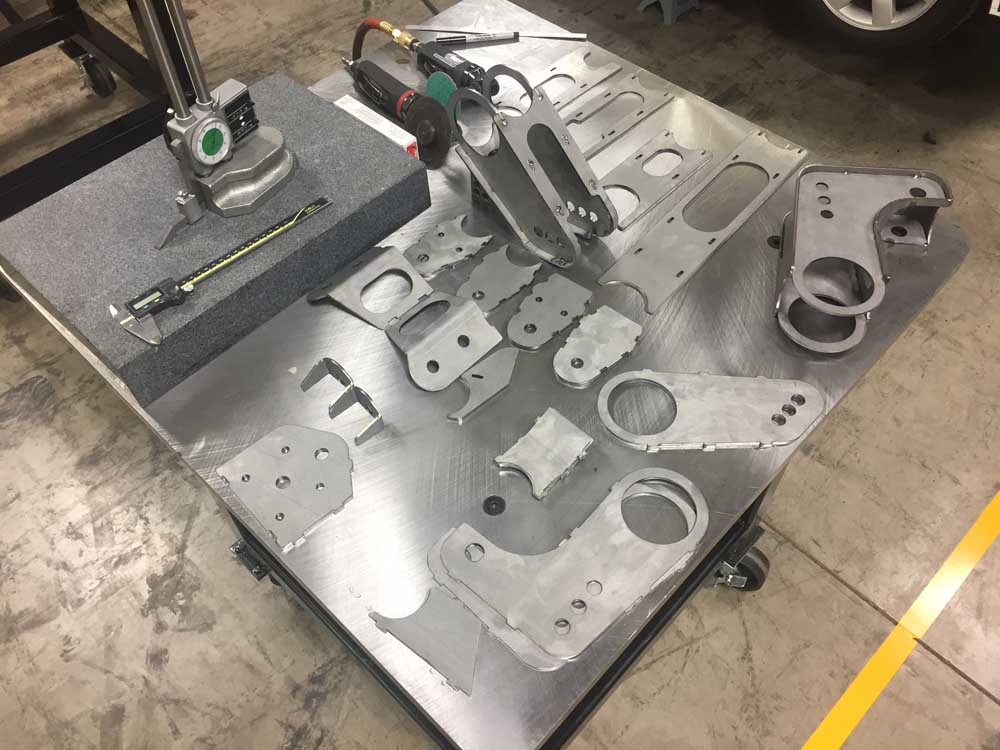

Rapid Prototyping

Rapid Prototyping! When we have an idea, we spit out the first concept FAST. The first working prototype went from napkin sketch to CAD model to real life in a hurry. It’s not meant to be pretty, and we tend to rely heavily on laser cutting, CNC bending and TIG...

CONTACT US

"A state of the art facility nestled in the foothills region of the North Carolina Appalachians."

Contact Info

- Monday-Friday: 8:00 - 6:00 // Saturday-Sunday: Closed

- 704-251-5069

- info@acmehpl.com

- 709 Performance Rd., Mooresville, NC 28115

Send A Message

Map & Directions

The Facility

Centrally located just a short drive east from I-77 in Mooresville, NC, the area is typically host to mild weather, making travel, vehicle delivery and construction virtually painless.

The facility contains a full complement of metal-shaping equipment, vehicle lifts, the latest in Miller Welders, all-new vehicle diagnostic/repair machinery, multiple “clean room” assembly areas, indoor vehicle storage, full security system, ample parking for trucks and trailers, adequate space for club cruse-ins or other get-together functions, a full kitchen/dining area, spare office work areas, children’s playroom and PowerPoint/video presentation equipment.